Aloft Forums

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ridge Runt Evo

- Thread starter Wayne

- Start date

Woohoo, great to see the build and the pup! Nice building room. Lots of good light. Will get going on the wing tomorrow after taking care of the criticals in the morning. . Sorry for the delay.

---> Curious - How much time do you think you guys took to build your fuselages?

It really means a lot to hear the good reports. As you know we have been chipping away at the design and manufacturing side of kitting and each project we tackle is more complex and more refined. I will be the first to admit that my CAD skills are weak, so this all takes me a bit longer. All of the guys at Aloft contribute to the design, hardly an afternoon goes past without us discussing some part of some project. We are a small shop, and we all wear a lot of hats here and I think we all love the challenges of design.

A little side note. During the early part of the design I worked with @Jarron for a motor to design around. We were going to have about 2mm clearance on the sides of the motor. Perfect. Well, we added the thin plywood in the nose area, that ate up that clearance. Yikes! Did not catch this until the kits had shipped. No worries a slightly smaller motor will actually fit better and work better since the AUW was lower than originally expected. Woohoo. (We could also alter the plywood design to give back the motor clearance.)

I just wish I had got the kit out a little sooner to give folks more time to build, but in the end, the extra time spent makes the model very easy to build.

thenated0g

Moderator

this?

Just posted some photos with the motor installed. I have to admit that I was not sure I'd be able to use this fuselage as I had sanded as a glider nose, how bad will the spinner fit up be?. I'm a bit shocked to discover it fits this well considering the glider nose is not symmetrical vertically.

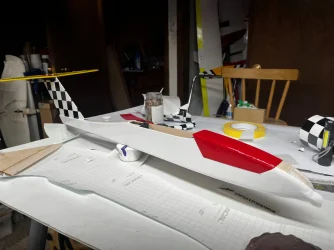

Still need to sand my ailerons, I didn't have access to a flat building surface today for that step. Trying to figure out what colors I'll use. Thinking translucent Red with White and a bit of CarbonFiber.

Hey on the plus side as an electric I don't have to cover a nose.

Still need to sand my ailerons, I didn't have access to a flat building surface today for that step. Trying to figure out what colors I'll use. Thinking translucent Red with White and a bit of CarbonFiber.

Hey on the plus side as an electric I don't have to cover a nose.

thenated0g

Moderator

i think we have too many Ridge runt threads

Wayne.

Is there no chem. solution that will clean the graphite parts? ! hate that black dust, it gets into everything!

I am thinking of making the B1 bulkhead 1/16" wider to obtain a better fit up with the spinner

and give the motor a wee bit more room. Actually a 1/32" sheet balsa shim all of the way around

the bulkhead might not hurt also to keep from running out of triangle stock in the corners.

Tom

Is there no chem. solution that will clean the graphite parts? ! hate that black dust, it gets into everything!

I am thinking of making the B1 bulkhead 1/16" wider to obtain a better fit up with the spinner

and give the motor a wee bit more room. Actually a 1/32" sheet balsa shim all of the way around

the bulkhead might not hurt also to keep from running out of triangle stock in the corners.

Tom

Will finish covering and then finish out the install as I want to see where the CG comes in at.

Wider motor area - You can just trim the plywood doubler where the motor is sitting. this will give plenty of room. As it is, we have plenty of room, nothing is touching. We have already modified the plywood for the next batch of models.

Wider motor area - You can just trim the plywood doubler where the motor is sitting. this will give plenty of room. As it is, we have plenty of room, nothing is touching. We have already modified the plywood for the next batch of models.

thenated0g

Moderator

Oh good that means you have to finish the hotwire kit