Yotaman1985

Very Strong User

Hey guys,

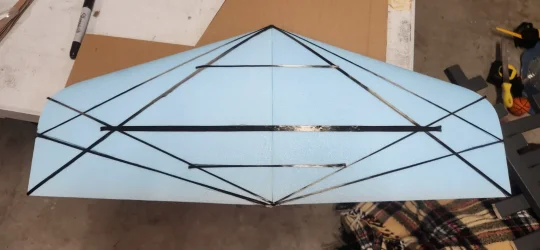

I'm venturing into unknown territory here and starting my first composite bagged wing build. After my mostly successful experience with the Z1 wingtip fins and the desire for a Gizmo style plank after seeing some at Sunset, I have designed a plank with some help from Nate. This is my first time designing a plane and having cores cut so we will see what happens but I am excited to learn along the way.

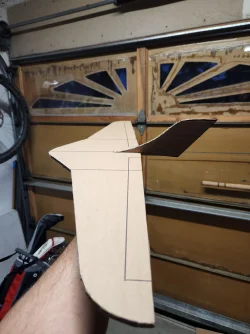

I decided to name it the Mini Buzz and it will be a 30" Blended wing plank with a center vertical fin much like the Gizmo I took inspiration from. The vertical fin will be removable and I havent decided yet if the wing will be one piece or able to split into two. It will be using a PW51 airfoil and will be bagged in carbon fiber.

Ill try to post updates on how the build goes and any questions/problems I run into. Pics are of the 3d model I made for measurements and a cardboard cutout so I could hold it for size reference.

Special thanks to Nate for all the help so far!

I'm venturing into unknown territory here and starting my first composite bagged wing build. After my mostly successful experience with the Z1 wingtip fins and the desire for a Gizmo style plank after seeing some at Sunset, I have designed a plank with some help from Nate. This is my first time designing a plane and having cores cut so we will see what happens but I am excited to learn along the way.

I decided to name it the Mini Buzz and it will be a 30" Blended wing plank with a center vertical fin much like the Gizmo I took inspiration from. The vertical fin will be removable and I havent decided yet if the wing will be one piece or able to split into two. It will be using a PW51 airfoil and will be bagged in carbon fiber.

Ill try to post updates on how the build goes and any questions/problems I run into. Pics are of the 3d model I made for measurements and a cardboard cutout so I could hold it for size reference.

Special thanks to Nate for all the help so far!