Yotaman1985

Very Strong User

How do you guys usually hold servos in while gluing? My method this time is a tin full of lead bbs precisely balanced on a mixing cup...

I have heard this a few times.... Can't wait!The more I retire, the busier I get.

That would be perfectI like that method.

We have some 1" x 1.125" tungsten slugs kicking around that are perfect for the job.

Ive got some cheap plastic clamps for this reason but unfortunately couldnt reach this one so I had to get creative. Loli do something similar or if its close to an edge some light clamps

For this reason I try to always use some sort of mount. My photo is really a servo in an LDS mount and I am gluing the mount into the wing. I have a layer of plastic (plastic sandwich bag) between the servo and the frame so the servo doesnt get glued in. The tail of the Forza is really tight and designed to glue in the servos so not quite sure what I am going to do there as I would really like them to be removable if possible.For you all that epoxy your servos right to the wing: how much of a pain is it to remove them if one dies? I've always stuck with bolting or hot glue as servo replacement is a regular part of my treebashing.

Wrap them in tape then all u do is cut the tape off to remove the servoFor you all that epoxy your servos right to the wing: how much of a pain is it to remove them if one dies? I've always stuck with bolting or hot glue as servo replacement is a regular part of my treebashing.

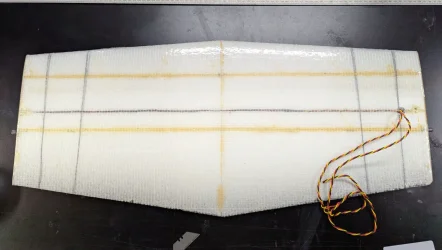

Hi Yota, I just use a small cylinder of PE foam a bit longer than the gap between the last slug and the end of the tube. It's simple, cheap, and provides a buffer if the nose stops quickly.Got most of the fuse finished off today. Epoxied in the ballast tube and avionics tray. Decided to make it a top load ballast tube and Im working on designing a spring loaded, 3d printed stopper for it. Also fit my battery and designed/3d printed a mount for my reciever. Going to custom make all the servo wiring so its the perfect length too. Waiting on some more epoxy to arrive so I can install the elevator/rudder servos. Almost there!

View attachment 22451

Thanks Doc,Hi Yota, I just use a small cylinder of PE foam a bit longer than the gap between the last slug and the end of the tube. It's simple, cheap, and provides a buffer if the nose stops quickly.

Lovely neat build by the way.

Cheers,

Doc,