G-man

Very Strong User

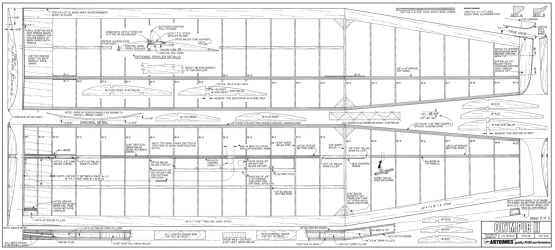

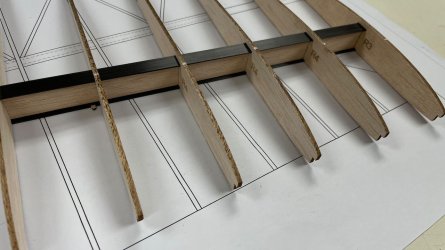

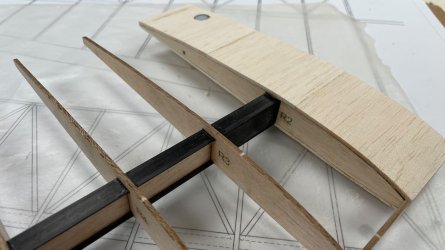

This is going to save substantial building time, and eliminate some head-scratching,

the persistent, "Did I make the wing joiner receiver tube mounts strong enough?"

the persistent, "Did I make the wing joiner receiver tube mounts strong enough?"

Attachments

Last edited: