apriliamille

User

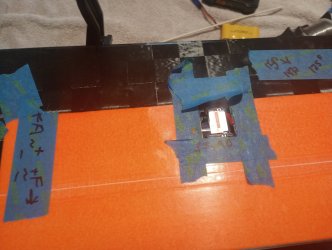

Well figured I would share my attempt at building this model. I got the Cubic this year from Aloft

I have never built something targeting at the precision of building like this. Others might say "pfft child's play" but its new to me as my prior build experience has been building 25 percent to 35 percent yaks, extras, edges etc etc. So here it goes. This is gonna be a slow build so i dont mess up and i still have to work

Initial measurements and thoughts i have on gear

total kilogram 0.994

plane 0.691

Fuse 0.078

RW 0.252

LW 0.246

Rudder 0.023

Boom 0.03

Parts bag 0.062

electrics 0.303

kst x6 0.06

motor 0.072 (tbd pending how much weight i need to cg the plane i will order motor of appropriate weight)

rx 0.01 TW R10 (this glider looks to have a pure carbon fuse so i want the 3 antennaes to go out of the fuse)

esc 0.028 talon 35

Spinner 32 0.013

props 0.006

3s 1000 ? 0.069

noobie misc 0.03 (glue, wire)

castle bec 2 6-8v 0.015 (why not. its some added weight but im intrigued of actually having servos that can handle some voltage beyond an esc bec

I have never built something targeting at the precision of building like this. Others might say "pfft child's play" but its new to me as my prior build experience has been building 25 percent to 35 percent yaks, extras, edges etc etc. So here it goes. This is gonna be a slow build so i dont mess up and i still have to work

Initial measurements and thoughts i have on gear

total kilogram 0.994

plane 0.691

Fuse 0.078

RW 0.252

LW 0.246

Rudder 0.023

Boom 0.03

Parts bag 0.062

electrics 0.303

kst x6 0.06

motor 0.072 (tbd pending how much weight i need to cg the plane i will order motor of appropriate weight)

rx 0.01 TW R10 (this glider looks to have a pure carbon fuse so i want the 3 antennaes to go out of the fuse)

esc 0.028 talon 35

Spinner 32 0.013

props 0.006

3s 1000 ? 0.069

noobie misc 0.03 (glue, wire)

castle bec 2 6-8v 0.015 (why not. its some added weight but im intrigued of actually having servos that can handle some voltage beyond an esc bec

Last edited: