Actually Flight test has a good active forum that

thenated0g has been very active on. I am very pleased he is posting up here also.

I have never used a vacuum pump when sheeting wings with wood, I have always used contact cement and basically rolled the wood onto the foam cores. The bagging should give better results. I don't think your foam will be smooshing down under the vacuum, but it is a valid concern. I forget what you said you used for a pump. Somewhere around here I have a really nice pump. I bought it as a rebuild from a guy that gets them from dental places. It is basically the same as used for commercial A/C repairs.

I have seen a wide range of things used for vacuum pumps ranging from pretty low end stuff like hand pumps from auto parts stores, converted fish air pumps, neither of these worked well. The most common seems to be an old refrigerator compressor, and semi-cheap vacuum pumps from the composite shops. These tended to be good and have a fair price. More recently I have heard of people using vacuum pumps from diesel cars, seems the newer cars have electric pumps that can be had for very little. Look for diesels that still have vacuum boosters for the brakes, they will have some sort of pump.

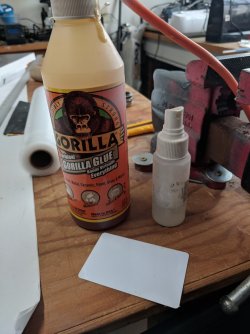

When it comes to glue for the skins, you can use anything that will not melt your foam. I have seen people use elmer's, all forms of contact cements, foam glues, Gorilla, epoxies even carpet tape in the old days.

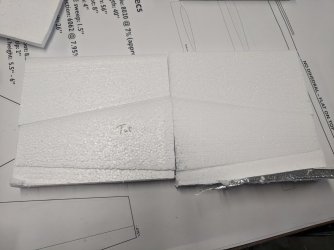

For skins we used to hit up a wood importer in So Cal that would bring in pallets of 5 layer ply that was 1/64". This was super nice stuff. Seems it was usually destine for high end cabinets. It was not cheap. The hobby suppliers will milk you dry for lower quality 3 layer 1/64" ply, so best off looking elsewhere if you really want this spec of ply. For balsa, I liked a good quality balsa that was around a 1/16 or even 1/8" thickness. I was usually looking for a light wing that I could sand nicely. I would not use balsa for anything that was going to be abused.

We had a guy sheet some EPS cores with aluminum sheets, do not do this! His cores melted while sitting in the sun. They looked pretty darn cool before they got too hot. Again, if you can glue it, you can use it.