A couple of observations from my recent IDS installation.

First, the molded parts can be kind of cranky to fit together and with pins and splines. A heating with a hot-air gun does make them more compliant and easy to work with.

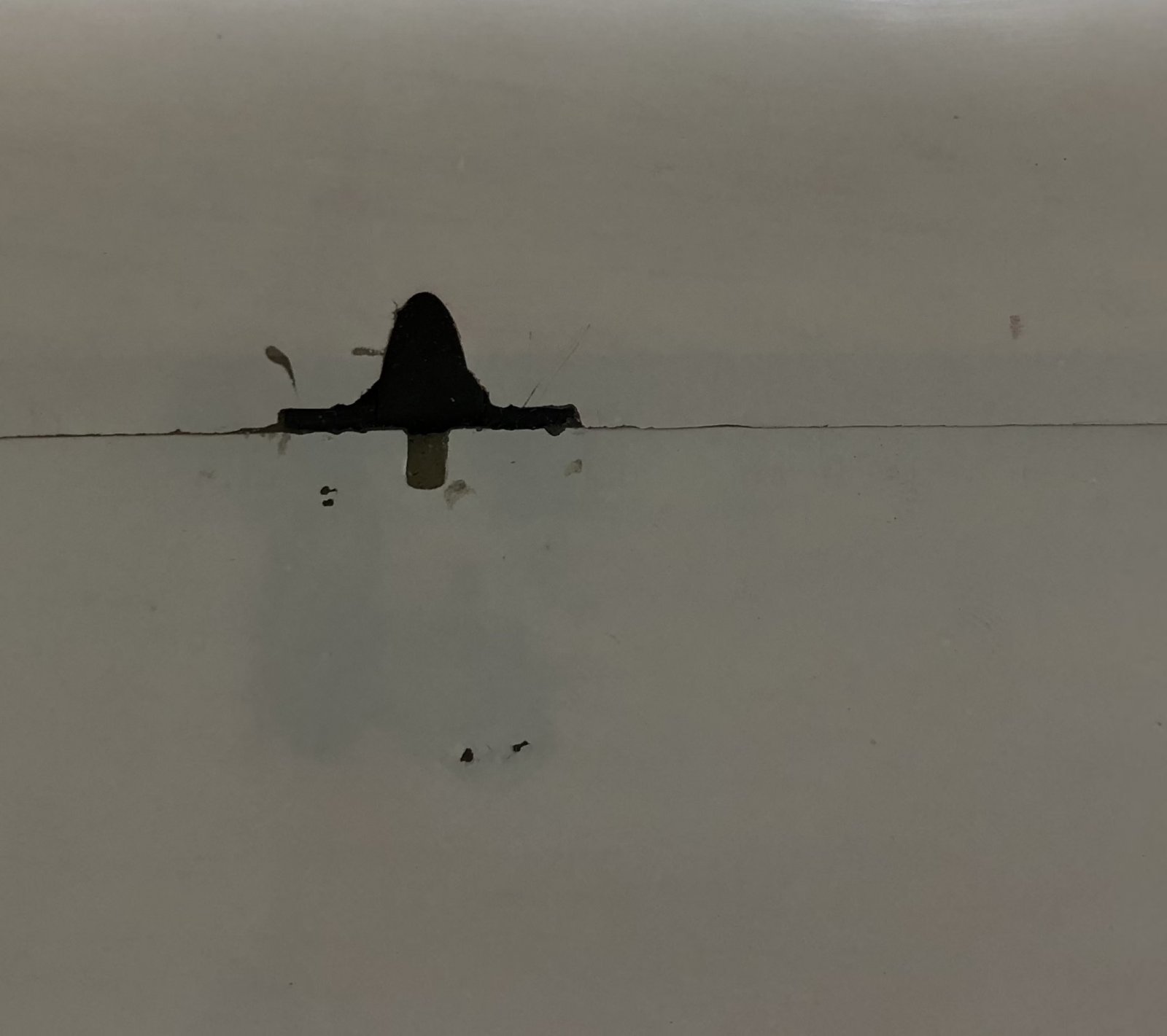

Second, a Tee Pin is a good temporary axle pin during installation. It's just slightly smaller in diameter than the steel pins supplied with the IDS and the extra length enables you to better align the hinge axis with the edges of the control surface. You can actually align the X and the Y axis's from the different vantage points. The photo below is an example.

Third, the new orientation of the new molded pushrods is a bit confusing. The 'bent' end goes at the servo end and the smooth side goes up. There is a ridge on the underside of the arm that actually meshes with the grooves in the rotary servo arm.

Another thing that is helpful, is to prepare the hinge pin area of the pushrod by using a hot-air gun to melt paraffin into the hole and surrounding areas so that its lubricated and glue won't stick.