Doc James Hammond

Very Strong User

Hey Guys,

Flying F3f planes or in fact most slope planes these days you need to carry ballast, lugging it all over the topography which is par for the course. Actually, pretty much anything will do to contain it as it can't go far.

Its only when you have to put it in the hold of an airliner plane or something that it gets a bit of a problem as the the weight in such a compact bunch makes it quite damaging should it somehow break loose. I have tried various fishing boxes made of plastic etc and some of them were Ok but all broke eventually.

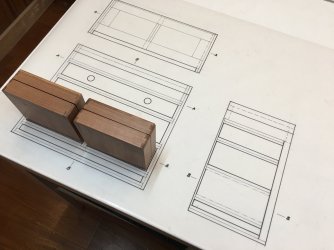

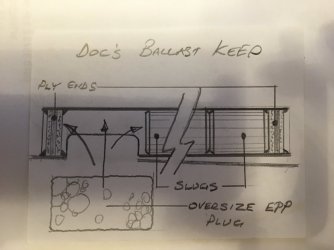

Since I now use two types of ballast: 19mm round Tungsten Copper slugs, and recently 20mm square brass ones the problem has doubled - so I decided to make a bespoke ballast box - or in fact two fo them, one for each type, and also to hold the wooden spacers as a set.

So here is the result.

Wood incidentally, is recycled Vietnamese Red Cedar.

Cheers,

Doc J.

Flying F3f planes or in fact most slope planes these days you need to carry ballast, lugging it all over the topography which is par for the course. Actually, pretty much anything will do to contain it as it can't go far.

Its only when you have to put it in the hold of an airliner plane or something that it gets a bit of a problem as the the weight in such a compact bunch makes it quite damaging should it somehow break loose. I have tried various fishing boxes made of plastic etc and some of them were Ok but all broke eventually.

Since I now use two types of ballast: 19mm round Tungsten Copper slugs, and recently 20mm square brass ones the problem has doubled - so I decided to make a bespoke ballast box - or in fact two fo them, one for each type, and also to hold the wooden spacers as a set.

So here is the result.

Wood incidentally, is recycled Vietnamese Red Cedar.

Cheers,

Doc J.

Attachments

Last edited: